On grading the symmetry of round brilliant cut diamonds

Table of Contents

- Abstract

- Introduction

- Grading the symmetry of round brilliant cut diamonds in Russia

- Grading the symmetry of round brilliant cut diamonds at HRD (Belgium)

- Grading the symmetry of round brilliant cut diamonds at GIA (USA)

- Composite table of symmetry distortion grading

- Variety of problems that arise when using the current symmetry grading systems

- Symmetry axes of a diamond

- Axial symmetry matrix

- Major and minor symmetry distortions

- Conclusion

- References

Abstract

The approach to grading the symmetry of round brilliant cut diamonds, developed in Russia, Europe, and USA, is considered. Knowledge on diamond cut technology is used to analyze the reasons of some important cases of asymmetry. A more objective method is proposed for grading these cases. The method implies composing a matrix of mutual axial deviations on the basis of a scanned 3D model of the diamond.

Introduction

When grading a diamond, one of the key characteristics is the symmetry of the stone. Though there is no conventional definition what the symmetry of a diamond is, the approach adopted in different countries and used in various grading systems implies fixing and grading certain deviations of its geometry, pattern, and visible image from the ideally regular, symmetric ones. These deviations may be either observable with the naked eye or with a 10x loupe, or detected by some measuring devices. A wide spread of various measuring devices, including those using a diamond scan technology, raised the question "How the deviations measured by such a device should be interpreted in the framework of a certain grading system developed earlier?" Another question arose when structural illumination schemes, such as "Firescope", "Idealscope", or "Hearts and Arrows Viewer", became popular. The pattern observed under such illumination conditions allows the observer to estimate the visual symmetry or asymmetry of the diamond under study. However, the data obtained in such a way do not correlate with symmetry grading tests performed in gemological laboratories. This caused the concept of "optical" symmetry to appear, which is not the same as traditional symmetry. Consider the existing approaches used to grade the symmetry of a diamond. Starting from this point, let us confine ourselves to a single diamond shape, namely, the round brilliant cut with 57 facets. This cut is most widespread and, ideally, it has an 8th-degree symmetry axis. This is the cut, whose symmetry the most strict requirements are applied to, while grading the cut quality and symmetry of this particular shape is best developed by gemologists. When grading the symmetry, different distortions are usually divided into more and less important ones. For example, the Gemological Institute of America distinguishes between "major" and "minor" symmetry. This paper is mainly focused on considerable distortions of symmetry and the necessity to improve grading these.

Grading the symmetry of round brilliant cut diamonds in Russia

In Russia, there are certain specifications used both to cut diamonds and to grade them. These specs have been developed at «Kristall» factory (Smolensk) and are referred to as TU 117-4.2099-2002 (Diamonds, 2002). According to these specs, the cut quality of a round brilliant cut diamond can be graded as «A», «B», «V», or «G» (the «°» grade is the best). A stone whose cut quality does not fit even the «G» level is considered as not compliant with the specifications. The specs contain the tolerances for cut parameters of «°»- and «B»-graded diamonds and the requirements whose violation should be treated as asymmetry. For the «°» group, the allowable error in the girdle roundness is 0.06 mm for stones with a diameter less than 3.00 mm, 2% of the diameter for stones with a diameter from 3.00 to 5.00 mm, and 0.10 mm for stones with a diameter exceeding 5.00 mm. For the «B» group, this error is 0.08 mm for stones with a diameter less than 3.00 mm, 2.5% of the diameter for stones with a diameter from 3.00 to 5.00 mm, and 0.13 mm for stones with a diameter exceeding 5.00 mm. For the «°» group, the displacements of the culet and table center with respect to the diamond axis must not exceed: 2% of the stone diameter for a diamond with a weight less than 0.30 ct, 1.5% of the stone diameter for a diamond with a weight from 0.30 to 0.99 ct, and 0.5% of the stone diameter for a diamond with a weight exceeding 1 ct. For both groups «A» and «B», the allowable irregularity of the girdle thickness (the difference between the maximum and minimum values of its local thickness) is 25%, and for those diamonds heavier than 1 ct the girdle must be visually uniform along the whole perimeter. The upper facets should be above the lower ones. For diamonds whose weight is less than 1 ct, the allowable displacement of upper edges and nodes with respect to lower ones is: 10% of the base of an upper girdle facet or crown facet for the «A» group and 20% of that figure for the «B» group. When an «A»- or «B»-graded diamond whose weight exceeds 1 ct is viewed through a 10x loupe, all its upper cut elements must be visually symmetrical to the corresponding lower cut elements. The difference in the tilt angles of both upper and lower facets with respect to the girdle plane, measured for a single diamond, cannot exceed: 1° for the «A» group, 2° for «B», 3° for «V», and 3° for «G». There are also some requirements for additional facets.

After a diamond is cut, it is passed to the quality control department, members of which, guided by the specifications, may claim: non-roundness (code 06), over- or undercut (code 11), top-to-bottom displacement (code 16), table displacement (code 17), girdle displacement (code 19), crooked girdle (code 23), and some more flaws.

Grading the symmetry of round brilliant cut diamonds at HRD (Belgium)

Consider now a symmetry grading approach adopted in Europe, for example, the one developed at HRD (Hoge Raad voor Diamant, that is, Diamond High Council), Belgium. When grading the cut quality of a diamond, three proportion groups (very good, good, and unusual) and four finishing groups (very good, good, medium, and poor) are used. Possible distortions of symmetry mostly affect the finishing grading, as well as exterior features, such as polishing errors, do (HRD, 1997).

To grade the finishing, the following rules are used:

- Very Good – flaws are very hardly observable with the naked eye, that is, observable only after their location is somehow determined,

flaws are hardly findable using a 10x loupe or microscope, that is, become conspicuous only after they are localized.

- Good – flaws are hard to find with the naked eye; they are not conspicuous, but clearly visible after they are somehow detected,

flaws are fairly easy to find, can be noticed, but do not strike one’s eye.

- Medium – flaws are easy to find with the naked eye,

they are striking when a 10x loupe is used,

they affect the brilliance of the stone.

- Poor – symmetry deviations are very striking and hindering, that is, are evident,

asymmetry distinctly affects the brilliance of the stone.

Four types of symmetry distortions are considered as the key ones. These are: deviation of the girdle shape from circular (out–of–round), variation of crown height or pavilion depth, off-axis displacement of the culet (culet’s eccentricity), and off-axis displacement of the table (table’s eccentricity) . The girdle non-roundness is measured by a micrometer, while the rest of the distortions are revealed by means of a proportionscope or microscope. There are less important symmetry distortions as well, some of which may also affect the appearance of the stone. These are:

- wavy girdle, due to a decrease in the tilt angle of two opposite pavilion facets (this may cause the effect of local darkening, similar to the «bow-tie» effect peculiar to marquises and some other elongated fancy cuts);

- alternating girdle thickness;

- cone-shaped girdle;

- lower main facets do not align with upper main facets.

Additional facets and some other symmetry distortions are considered as minor, because they do not considerably affect the appearance of the stone and its perception by the observer.

If any of the key symmetry distortions is revealed, it should be measured and normalized to the average diameter of the girdle. Table 1 illustrates the relation between the values thus obtained and the resultant finishing group the stone belongs to:

| Very good | Good | Medium | ||

| G | G* | |||

| out-of-round girdle | < 2% | < 3% | <= 4% | > 4% |

| crown height variations,due to sloping table or wavy girdle;variation of pavilion depth | < 2% | <= 3% | < 4% | >= 4% |

| culet’s eccentricity | < 2% | <= 3% | < 4% | >= 4% |

| table’s eccentricity | < 2% | <= 3% | < 4% | >= 4% |

G* - if the distortion is observed two or more times, the grade is decreased to Medium.

Grading the symmetry of round brilliant cut diamonds at GIA (USA)

The Gemological Institute of America (GIA) also divides finishing grading into symmetry grading and polishing grading (GIA Diamond Grading, 1993). When a symmetry distortion affects the appearance of the diamond or indicates some special efforts of the manufacturer willing to save the diamond weight, such a distortion is considered as a proportioning flaw. The noticed major symmetry distortions are listed in that worksheet area meant for proportioning (which is not graded), while minor ones are referred to finishing. Main symmetry distortions that may be found in a round brilliant cut diamond include both those always considered minor and those which, under certain conditions, can be considered major. These distortions may be of the following types:

- off-center culet;

- off-center table;

- misshapen facets;

- the table is not a regular octagon;

- non-parallelism of the table and the girdle;

- out-of-round girdle outline;

- misalignment of crown and pavilion facets;

- facets not properly pointed;

- wavy girdle;

- additional facets (naturals and extra facets).

The symmetry is tested first with a 10x loupe, then with the naked eye. All the symmetry distortions, which evidently affect the appearance of the stone, are considered major. The more frequent of these are the following:

- table or culet noticeably off-center, observed through a 10x loupe;

- girdle outline out-of-round, observed with the unaided eye;

- evident non-parallelism of the table and the girdle or evident waviness of the girdle, observed through a 10x loupe;

There are the following symmetry grades: “Excellent”, “Very good”, “Good”, “Fair” and “Poor”. However, such a grade concerns only the minor symmetry distortions, so the major ones should not be graded or divided into any classes. Nevertheless, if a diamond has at least one major symmetry distortion, its symmetry can be graded only as “Fair” or “Poor”.

Composite table of symmetry distortion grading

Table 2. Composite table of symmetry distortion grading defined in different grading systems (allowable deviations from the ideal shape, at which the symmetry is still considered as good) for a round brilliant cut diamond with a weight of 0.50 ct. Major deviations are marked in bold.

| Distortion | Allowable magnitude | ||

| TU (Russia) | HRD (Belgium) | GIA (USA) | |

| Out-of-round girdle | 0.1 mm | <= 4% | cannot be noticed with the naked eye |

| Table displacement | 1,5% | < 4% | observable through a 10x loupe, not striking |

| Culet displacement | 1,5% | < 4% | observable through a 10x loupe, not striking |

| Table inclination | not defined | crown height variation < 4% | observable through a 10x loupe, not striking |

| Wavy girdle | cannot be noticed with a 10x loupe | crown height variation < 4% | cannot be noticed with a 10x loupe |

| Crown and pavilion displacement | 10% of girdle facet base | allowed | observable through a 10x loupe, not striking |

| Pointing error | cannot be noticed with a 10x loupe | allowed | observable through a 10x loupe, not striking |

| Improper shape of facets | cannot be noticed with a 10x loupe | allowed | observable through a 10x loupe, not striking |

| Non-uniform girdle | 25% of minimum thickness | allowed | observable through a 10x loupe, not striking |

| Additional facets | <= 4 (on the pavilion) | allowed | a few |

| Unequal angles | <= 1° | ---------- | ---------- |

Thus, examining the three diamond grading systems reveals both community of the approaches they use and some differences between them. It is worth noting that the concept of symmetry does exist in all the systems but is never defined clearly in any of these. Moreover, different systems differently assign symmetry distortions to either proportioning or finishing. In certain cases, special procedures of quantitative measurements are defined, but in some other cases they may be lacking. The Russian grading system takes into account deviations of the angles of crown and pavilion facets, the HRD system takes into account deviations of the crown and pavilion heights, while the GIA system does not consider these deviations as symmetry distortions.

Variety of problems that arise when using the current symmetry grading systems

Example 1. Tilted table. Consider a scanner, such as a Sarin one, which measures the facet tilt angles with respect to the table plane of the diamond being scanned. Should this plane be tiled with respect to the pavilion axis, the angles will be measured incorrectly. That is, instead of revealing that the pavilion is properly cut, all its facets making equal angles with the pavilion axis, and only the table is not good, the report will «claim» that the pavilion facets all have different tilt angles, that the cut is faulty, and that the stone should be either marked down or re-cut. Meanwhile, the right conclusion of the device would be the following: «all the pavilion facets make the same such-and-such angle with the pavilion axis, but the table is not perpendicular to the pavilion axis».

Let us see at the two tilted table diamonds. The diamond No.1 is taken form Internet (www.diamonds.net), and has the Sarin Report, see Fig 1.

Fig. 1. The Sarin report for this diamond reveals the considerable difference for the pavilion angles (from 40.8 to 42.6 degrees). Source: www.diamonds.net

Fig. 2 and Table 3 show the result of angle measurements on the base of the table plane for the first diamond example. Pavilion angles have variation 1.8 (from 40.8 to 42.6 degrees).

Fig. 2. The tilt angles of the pavilion facets measured by a Sarin scanner relatively to the table are 40.8 and 42.6 degrees, difference is 1.8 (minimum is marked in red, maximum in green color). Taking into account 0.8° displacement of the table axis and pavilion axis, we introduce the corresponding correction that changes the tilt angles to 41.7 and 41.8 degrees.

| Crown facets (bezel) | Pavilion facets | ||||||||

| Facet number 1 + 5 |

Facet number 2 + 6 |

Facet number 3 + 7 |

Facet number 4 + 8 |

Mean and variation | Facet number 1 + 5 |

Facet number 2 + 6 |

Facet number 3 + 7 |

Facet number 4 + 8 |

Mean and variation |

| 35.3 | 35.6 | 35.5 | 34.8 | 41.2 | 40.8 | 41.0 | 41.6 | ||

| 34.4 | 34.2 | 34.5 | 35.3 | 42.2 | 42.6 | 42.5 | 42.0 | ||

| 69.7 | 69.8 | 70.0 | 70.1 | 83.4 | 83.4 | 83.4 | 83.6 | ||

| 34.85 | 34.9 | 35 | 35.05 | 34.95° | 41.7 | 41.7 | 41.7 | 41.8 | 41.75° |

| Min | Max | Var 0.2° | Min | Max | Var 0.1° | ||||

Table 3. Diamond No. 1 measurements. Rows 1 and 2 – angles measured by a Sarin scanner; row 3 – the sums of the angles of opposite facets; row 4 – the average values of these angles.

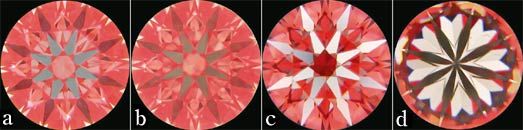

If one calculated the facet tilt angles on the basis of dihedral angles between opposite facets, the variations of the angles would be much smaller than those appearing in a Sarin report. According to such a report, the stone might get a low grade in symmetry. At the same time, the dihedral angle between opposite facets is what strongly affects the diamond cut quality. These dihedral angles are formed by pairs of the pavilion facets 1and 5, 2 and 6, 3 and 7, 4 and 8. If one has an intention to see such a tilted table diamond in an instrument like “Hearts and Arrows Viewer” the axis of the diamond should be combined with the axis of the instrument.

The diamond No.2 is owned by one of the authors (G.H). The parameters of this diamond with tilted table are shown in the Table 4. The crown and pavilion axes are tilted from table axis at the different angles. As the result the significant (approximately 1 degree) difference will be obtained if the angles will be measured in the base of the table plane. Meanwhile a good quality of such a stone is confirmed by «hearts and arrows» patterns obtained with structural illumination after its position was corrected on order to match the viewer’s axis (Fig. 3)

| Crown facets (bezel) | Pavilion facets | ||||||||

| Facet number 1 + 5 |

Facet number 2 + 6 |

Facet number 3 + 7 |

Facet number 4 + 8 |

Mean and variation | Facet number 1 + 5 |

Facet number 2 + 6 |

Facet number 3 + 7 |

Facet number 4 + 8 |

Mean and variation |

| 33.31 | 33.53 | 33.92 | 33.77 | 41.0 | 41.15 | 41.04 | 40.6 | ||

| 33.83 | 33.01 | 33.37 | 33.05 | 40.19 | 39.88 | 40.23 | 40.53 | ||

| 67.14 | 66.54 | 67.29 | 66.82 | 81.19 | 81.03 | 81.27 | 81.13 | ||

| 33.57 | 33.27 | 33.65 | 33.41 | 33.46 | 40.60 | 40.52 | 40.64 | 40.57 | 40.58 |

| Min | Max | Var 0.4° | Min | Max | Var 0.12 | ||||

Table 4. Rows 1 and 2 – angles measured by a Sarin scanner; row 3 – the sums of the angles of opposite facets; row 4 – the average values of these angles.

Fig. 3. a) Snapshot of the diamond No.2, made by means of an Idealscope. The diamond is positioned so that its table is perpendicular to the optical axis of the camera. An off-axis displacement of the culet and pale regions of partial light leakage through the pavilion can bee seen. b) Snapshot of the same diamond slightly rotated in order to compensate for the table tilt. The degree of optical symmetry became much higher, as a result. c) and d) Snapshots of the diamond made by means of a “Hearts and Arrows viewer” device, which demonstrate perfect «hearts and arrows» patterns.

Example 2. Distorted girdle shape. Among the symmetry distortions considered major in all the grading systems mentioned, the one being easiest to measure is, probably, the degree of girdle non-roundness (the deviation of its shape from a perfect circle). This is because the diameter of a diamond is quite easy to accurately measure at a sufficiently large number of places. Even if a diamond grading certificate does not mention this kind of symmetry distortion and its grade, the document anyway contains the minimum and the maximum diameter of the stone. These data allow one to calculate the variation of the girdle diameter on the basis of the difference between these two values.

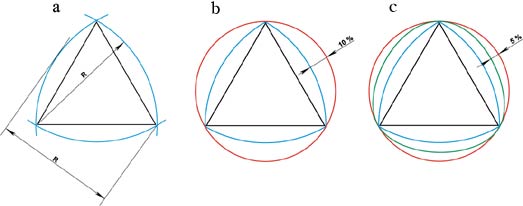

However, there is a geometrical figure different from the circle, which has the same diameter no matter what a direction it is measured along (the blue contour in Fig.4). If the girdle contour is something intermediate between this figure and a circle, the certificate of the diamond will contain no data prompting the consumer to suspect that the stone is not symmetric. However, such a shape of the girdle distorts the facet arrangement. First of all, it makes opposite facets non-parallel to each other, which dramatically changes the paths of light rays inside the diamond (See below the «Major and minor symmetry distortions» section to find more about the two angles that define the orientation of each facet).

Fig. 4. The girdle of a «triangular» diamond (green contour) weakly differs from a circle (red contour). According to expert conclusions and certificates, such a stone is «good» (any diameter of the girdle is the same), but, as a matter of fact, its symmetry is poor.

Example 3. Non-constant girdle thickness. The girdle of a round brilliant cut diamond has 16 thinner regions and 16 thicker ones. All the thinner regions are of the same kind, while the thicker ones can be divided into two types: main facet junctions and edge junctions. There are some diamonds in which the girdle thickness differs from one thicker region to another. For example, at the main facet junctions the girdle is thicker than at the edge junctions (see Fig. 4). This occurs when the upper and lower girdle facets are slightly tilted not with respect to the girdle plane but with respect to the diamond axis (azimuth angle deviation). Since many laboratories measure girdles at their thinner regions, their cut grades are not affected by the increase in the girdle thickness at its thicker region. This fact can be used to increase the average thickness of the girdle and therefore to increase the stone weight by 2-3%, sacrificing the optical properties of the diamond. (Increasing the girdle thickness not at the facet junctions but at the edge junctions, on the contrary, does not increase the weight but improves the optical properties of the stone. This idea is used, for example, by Eightstar Diamonds company).

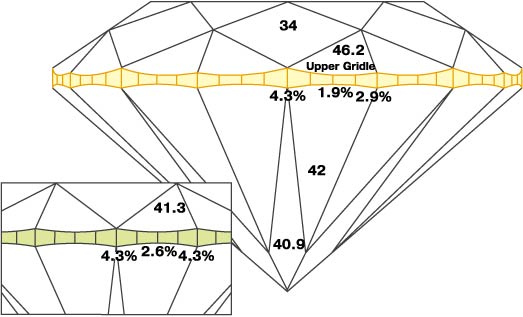

Fig. 5. The girdle of this diamond is perfectly made in the thinner regions in order to allow it to be graded as AGS 0. However, the thickness of the thicker regions of the girdle is increased in order to increase the weight yield of the stone. 46.2° tilt angle of twin upper girdle facets compensates for the thickened girdle. The inset shows a diamond with a usual girdle, in which the tilt angle of twin upper girdle facets is 41.3 degrees.

Fig. 6 illustrates real examples of two diamonds with the girdle shape as it described above.

Of course, we could give more such examples, but our goal is not to list all of these but to demonstrate the breadth of the problem. The problem is that in some cases those stones looking good are graded poorly, because they lack symmetry in accordance with the chosen symmetry grading system. On the other hand, some stones look bad and their actual symmetry is poor, but the current symmetry grading systems conclude that they are good.

Symmetry axes of a diamond

In our opinion, most serious problems arise when one tries to reveal and grade such symmetry distortions as deviations of the table, culet, and the angles of crown and pavilion facets. In diamond grading systems, these deviations are measured with respect to either the «center» of the diamond or its «axis». However, there is no «center» in a diamond; and even if we are talking about the «axis», some further specification is needed. Indeed, the girdle surface is formed because of rotating a raw diamond. So, it is a reasonable approximation to assume that the girdle surface is a portion of a cylindrical surface and therefore has an axis of revolution. However, this axis may be not perpendicular to the table of the diamond. This occurs, for example, when the table of a cut diamond is not perpendicular to its girdle plane. The crown of a diamond consists of three tiers, namely – star facets, crown facets, and upper girdle facets. During the cutting process, each tier is formed by rotating the raw diamond about the axis of the stone-holder of the cutting dop. Strictly speaking, each tier has its own axis of revolution. However, since all the facets belonging to the crown are being cut without taking the diamond out of the cutting dop, one can assume (with a high degree of accuracy) that the whole crown has a single axis of revolution (symmetry axis), except for the table. The pavilion consists of two tiers: pavilion facets and lower girdle facets. However, similarly to the case of the crown, it can be assumed that the pavilion has the only axis of revolution. Thus, a round brilliant cut diamond has four principal axes: the table axis, crown axis, girdle axis, and pavilion axis (see Fig. 6). Of course, in an ideal, perfectly symmetric diamond, all these axes merge into one, and the term «diamond axis» becomes clear. However, if we are going to describe an asymmetric diamond, we cannot just say that some element of the stone is displaced with respect to an axis, because we need to clearly specify which axis we are talking about. Determining the facet inclination angles also becomes a problem for a non-ideal diamond, because of lacking specification which axis these angles are measured relative to.

Fig. 7. The axes of different cut elements of a diamond (table, crown, girdle, and pavilion) appear during certain diamond cutting steps. These axes may differ from each other. In such a case, various types of symmetry distortions arise in the diamond.

Thus, to correctly grade the asymmetry of a diamond, one needs a method capable of independently determining each of these axes and calculating their mutual deviation. Since there are four mutually independent axes in a diamond, the result of such a calculation can be conveniently represented by a matrix (Table 5).

Axial symmetry matrix

Table 5. Degree of mutual deviation of the axes of a round brilliant cut diamond.

| Table axis | Crown axis | Girdle axis | Pavilion axis | |

| Table axis | 0 | 1 | ||

| Crown axis | 0 | 2 | ||

| Girdle axis | 0 | |||

| Pavilion axis | 3 | 0 |

In the above table, figures 1, 2, and 3 stay for those symmetry distortions considered major in the diamond grading systems discussed. Namely:

1 – displacement of the table;

2 – non-parallelism of the table and girdle;

3 – displacement of the culet.

After the measurement of the angles between the axes is over, the corresponding cells of the matrix are filled in with the data obtained. The analysis of such a matrix, first of all, allows one to reveal the true nature of the asymmetry if, for example, three of the axes coincide while the fourth is inclined. Second, the angles measured provide the possibility of evaluating how such-and-such symmetry distortion affects the appearance and optical characteristics of the diamond. For example, 1° tilt of the table plane results in approximately 2° deflection of a ray leaving the diamond (starting from here, table-to-crown rays are considered; and in the case of a crown-to-crown ray the difference is yet larger, because the tilt of the table almost does not deflects a table-to-table ray). Meanwhile, 1° error in the mutual arrangement of opposite pavilion facets results in 12-16° deflection of an output ray, which considerably distorts the visible distribution of brighter and darker regions in the diamond.

Among the main symmetry distortions, two types can be distinguished: the distortions of the first type are due to mutual deviations between the axes of the main elements of the diamond, while the second is due to asymmetry of individual facets belonging to the same main element with respect to the axis of this element. To grade the asymmetry described, it is not enough to simply measure all the possible cases of deviation from the ideal symmetry. In addition, one needs to evaluate the influence of each type of symmetry distortion on the appearance and resultant perception of the diamond. For example, variations of the angle between a pavilion facet and the pavilion axis belong to the second type, but the influence of this distortion on the optical characteristics of the diamond is stronger than that of non-coincidence of the table and pavilion axes.

Major and minor symmetry distortions

Not all of the symmetry distortions that arise during manufacturing a diamond are accidental. In some cases, the manufacturer purposely distorts the symmetry of the stone being cut. For example, he may get rid of an inclusion by changing the tilt angle of a single facet. This distorts both the shape of the adjacent facets and pointing of the adjacent edges. In such a case, to analyze the asymmetry on the basis of the scheme suggested, it is necessary to determine the position of the corresponding axis, the tilt angle of each facet with respect to this axis, and the maximum deviation of these tilt angles. This would allow one to reveal the «minor symmetry flaws», that is, minor distortions of the symmetry of the diamond. Thus, each cell of the matrix discussed above should be filled in with two figures: the first is the mutual deviation of the axes, characterizing the «major symmetry», while the second is the deviation of a particular facet from its position yielding the perfect symmetry. This figure characterizes the «minor symmetry».

When determining the parameters of a diamond facet, a single angle is conventionally measured (for example, the angle between the facet and the girdle plane). However, each facet is a part of a plane, and to unambiguously define the orientation of a plane, two angles are required, for example – the tilt angle and the azimuth. Many symmetry distortions are due to different azimuth inclinations of facets. For example, this can be a mutual tilt of opposite pavilion facets. These deviations may seem insignificant since they are not striking when the stone is examined with a loupe, but they are very important when one performs ray-tracing for the diamond.

The method suggested describes only a portion of those phenomena conventionally considered as symmetry distortions (for example, it does not describe additional facets). Therefore, it must not be used instead of the symmetry analysis methods existing so far. However, the data being the output of our approach characterize main symmetry distortions, both major and minor, allow one to understand the reason of these distortions, and provide a link between the output of a scanner, the diamond cut parameters considered by the existing diamond grading systems, and the appearance of the diamond whose symmetry is being analyzed. Therefore, we think that adding the suggested matrix to a diamond certificate (a gemological conclusion on the quality of the diamond) would inform the dealers and customers about some important features of the diamond cut quality.

Conclusion

In conclusion, we would like to note that the division of diamond symmetry distortions into «major» and «minor» ones arose on the market during last decades and that it is supported because training centers spread it when teaching gemologists. However, such a symmetry classification has some drawbacks: it analyzes neither the reasons leading to such-and-such symmetry distortions nor the influence of these distortions on the appearance and optical properties of a diamond. In this paper, we were trying to follow the definitions historically appeared on the market, and the concepts of «minor» and «major» symmetry we adopted do not always correspond with the degree of the influence of the symmetry distortions on the optical properties of the stone under study. This problem is worth being discussed separately, and so far we would only like to note that these distortions must be clearly distinguished, because, for example, actual variations of pavilion facet angles, caused by non-roundness of the girdle, have much stronger influence on the optical properties of the diamond than their quasi-variations caused by a tilt of the table. Meanwhile, the current reports of Sarin and OGI devices do not specify the reason of the angle variations, and leading gemological laboratories do not even mention these variations in their reports. The question still not answered is what major and minor symmetry distortions are with respect to two types of consumer’s perception of diamonds. The first type concerns the visual perception of the optical properties of diamonds, such as Scintillation, Brilliance, and Fire. Those symmetry distortions leading to degradation of the optical properties of a diamond can likely be considered as «substantial» or, even better, as «distortions affecting its optical properties». The second type concerns the visual perception of the quality of diamond cutting performed by the manufacturer. We attribute this type to the following symmetry distortions: table inclination, table displacement, culet displacement, edge pointing error, and upper facets displacement with respect to the lower facets. The quality of a diamond with respect to the symmetry of this type is especially clear to an expert equipped with a loupe. A high expert’s grade of the skill of the manufacturer who has succeeded in the symmetric, almost ideal geometry of the stone can, of course, affect the price of the cut diamond. Such symmetry distortions, or rather their absence, can be considered as an «illustration of manufacturer’s skills» or «assembling quality».

The authors wish to thank Mr. Pol Van der Steen (DiamCad, Belgium) for the example of a diamond with a «triangular» girdle.

References

1. Diamonds. Technical specifications. Classification. TU 117-4.2099-2002, pp. 10-13.

2. HRD – Institute of Gemmology, Diamond Grading Course Book, 1997. pp. 125 – 132.

3. GIA Diamond Grading. 1993. Assignment 9, pp. 2-15.

4. http://www.ideal-scope.com/